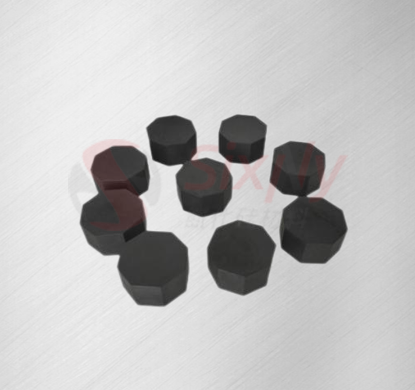

Silicon nitride gasket

Silicon nitride gaskets are designed for applications in extreme environments, especially those requiring high temperature resistance and superior insulation. Custom silicon nitride gaskets offer unmatched performance benefits in high temperature, high pressure and corrosive environments due to their superior heat resistance, mechanical strength and insulation. It not only improves the operational efficiency and safety of the equipment, but also meets the precise needs of specific industrial applications through its highly customized design, greatly extending the service life and maintenance cycle of the equipment, and is an indispensable high-performance component in modern industry.

Advantages of silicon nitride gasket products:

Good wear resistance : silicon nitride ceramic gasket has extremely high hardness and wear resistance, can be used under extreme conditions such as high speed, high temperature and high pressure, is not easy to wear

Good high temperature resistance : silicon nitride ceramic gasket melting point of up to 1900℃ above, can be used in high temperature environment for a long time, not easy to occur thermal expansion and deformation

Good corrosion resistance : silicon nitride ceramic gasket can resist acid, alkali and other corrosive environment, not easy to damage

Good oxidation resistance : there is an oxide film on its surface, which can effectively prevent the occurrence of oxidation reaction

Good insulation performance : silicon nitride ceramic gasket has excellent insulation properties, can be used at high voltage, not easy to leak

High mechanical strength : the bending strength at room temperature can be as high as 980MPa or more, and the strength will not decrease at high temperature

High thermal stability : small thermal expansion coefficient, high thermal conductivity, good thermal shock resistance, can maintain stability in high temperature environment

Stable chemical properties : in addition to hydrofluoric acid, does not react with other inorganic acids, can resist the erosion of many organic materials

Low density, small specific gravity : only 2/5 of steel, good electrical insulation

Silicon nitride gasket performance indicators :

Performance | Ⅰ | Ⅱ | Ⅲ | ||

Density/(g/cm³) | 3.15≤ρ≤3.25 | ||||

Elastic modulus/GPa | 270≤E≤330 | ||||

Poisson's ratio | 0.23≤μ≤0.29 | ||||

Coefficient of thermal expansion (room temperature to 500℃)/X10-6/℃ | 2.0≤α≤3.7 | ||||

Bending strength/MPa | Four-point test | ≥750 | ≥650 | ≥530 | |

Three-point test | ≥820 | ≥720 | ≥550 | ||

Vickers hardness(HV) | ≥1420 | ≥1330 | ≥1270 | ||

Fracture toughness | ≥6 | ≥5 | ≥5 | ||

Crushing load ratio | 40% | 35% | 30% | ||

microcosmic structure | Air hole/μm | ≤10 | ≤10 | ≤25 | |

Inclusion | 25<S≤50 | ≤4 | ≤8 | ≤16 | |

50<S≤100 | ≤1 | ≤2 | ≤4 | ||

100<S≤200 | 0 | ≤1 | ≤25 | ||

S>200 | 0 | 0 | ≤1 | ||

Ceramic product processing accuracy :

Item | Precision value | ||||

Dimensional exact values | Up to 0.001mm | ||||

Degree of finish | Up to mirror | ||||

The number of concentricities | Up to 0.003mm | ||||

The number of parallelism | Up to 0.002mm | ||||

Bore tolerance | The minimum can be machined 0.005mm | ||||

Straight groove | The narrowest machined groove is 0.1*100mm | ||||

Thickness dimension | Minimum machining to 0.08mm | ||||

Screw thread | Min machining inner thread M2, outer thread no limited | ||||

Cylindricity dimension | Up to 0.004mm | ||||

Linear tolerance | Up to 0.001mm | ||||

Min aperture | The minimum processing capacity is 0.07mm |

The application of Silicon nitride ceramic gaskets :

It can be used to manufacture mechanical equipment bearings, seals, turbine blades, etc.

19194976688

19194976688